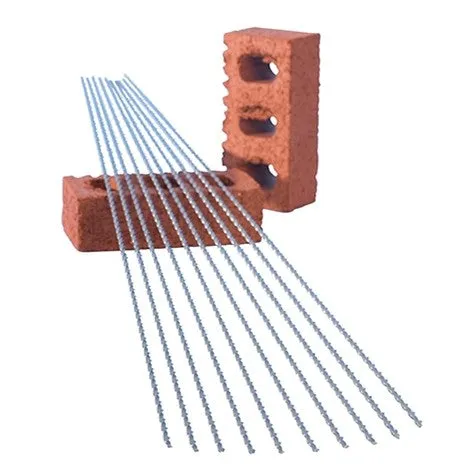

Thor Helical Crack Stitching Bars provide an effective solution for repairing and reinforcing cracked brickwork.

Thor Helical Crack Stitching Bars are bonded across cracks in walls with W60 Flexi Grout to reconnect and strengthen masonry.

Supplied in (W) 6mm x (L) 1000mm or (W) 8mm x (L) 1000mm sizes.

Description

Thor Helical Crack Stitching Bars

Thor Helical Stainless Steel Crack Stitching Bars have a tensile strength that is double that of conventional rebar and a spiral twist that permits a degree of torsional yield within elastic limits and provides an excellent key for bonding into mortars.

is a high-performance shrink compensated cementitious grout, which rapidly develops compressive strength, formulated to bond crack stitching bars in masonry walls. The structural repair system integrates the axial strength and elasticity of Thor Helical Bars with the properties of W60 Grout to enhance the tensile, shear and flexural capacity of masonry walls.

Anchored across fractures, the Thor Helical Crack Stitching Bars progressively accumulate building loads and disperse them back into the structure, spreading loads and strengthening cracked walls. This effective masonry stitching repair provides resilience against further cracking with minimal cost and little disruption.

Product Benefits:

-

Deep interlocking helix offers excellent bonding characteristics.

-

Increases tensile and shear strength of masonry.

-

Accommodates thermal and moisture movement.

-

Absorbs stress to redistribute load.

-

Minimal disturbance and fully concealed repair.

-

Quick, reliable and cost effective.

Product Specification:

Typical Performance Loads in 35-40mm slot at 400mm embedment length (taken from CE Mark Testing).

BS EN 845-1:2013 National Annex NA states that the bars need to provide an equivalent performance to the prescriptive 30mm x 5mm lateral restraint straps and the tension straps should have a declared tensile load capacity of at least 8kN.

| Bar Diameter | Bars Per Joint | Tension Load |

|---|---|---|

| 6mm | Single Bar | 8.39kN |

| Double Bar | 16.00kN | |

| 8mm | Single Bar | 11.06kN |

| Double Bar | 17.65kN |

Single bars bedded 20mm deep: Double bars placed 15 & 25mm deep: Triple bars buried 10, 20 & 30mm deep. Height of slot at least 3mm greater than diameter of crack stitching bars.

Typical Mechanical Properties of Thor Helical Profiled Bars

| Bar Diameter | CSA (mm²) | 0.2% Proof Stress (N/mm²) | Ult Tensile Strength (N/mm²)* | Mean Tensile Capacity # |

|---|---|---|---|---|

| 6mm | 8 | >870 | 1025 - 1225 | 9 kN |

| 8mm | 13 | >790 | 1025 - 1225 | 14 kN |

* Ultimate Tensile Strength is measured within a calibrated tolerance of /- 2%

# Mean Tensile Capacity is an indicative value derived from CSA x Mean UTS

Application

Application Method:

-

Grind out mortar bed to a depth of 30mm for half brick wall or 40mm full brick wall, 500mm either side of the crack.

-

Clear debris from the slot and thoroughly flush out with water.

-

Pump a bead of grout to the back of the slot to approximately 10mm from the surface.

-

Push Crack Stitching Bar half way into the grout-filled slot, trowel back displaced grout and repoint.